To craft Nichirin Blades, procure top-grade steel from Honjo Metals for longevity. Select high-quality ores for strength. Forging aligns molecules for durability. Symbolic color choices reflect your essence. Shape meticulously for balance and cutting ability. Guarantee gradual cooling and precise tempering. Adorn with unique designs using colors that hold meaning. Test rigorously for sharpness and resilience. If interested, uncover the intricate details behind each step to master the art of crafting these powerful swords.

Key Points

- Select high-quality steel from Honjo Metals or affordable options from Kajiya Supplies for longevity and performance.

- Use high-quality ores to determine blade strength and sharpness, aligning molecules for durability.

- Shape the blade with precision, focusing on curvature, tempering, and cooling for balance and strength.

- Add unique designs with symbolic colors, applying them meticulously for a flawless finish.

- Test the blade rigorously for strength, spiritual energy, resilience, sharpness, and durability to ensure quality.

Materials Required for Crafting Nichirin Blades

To craft Nichirin Blades effectively, you'll need to gather specific materials that are essential for ensuring the blade's quality and durability. When considering blade composition and customization, it's important to select high-quality steel that can withstand intense battles. Suppliers such as Honjo Metals provide top-grade steel known for its strength and resilience, making it a recommended choice for crafting Nichirin Blades. While premium steel comes at a higher cost, it guarantees the longevity and sharpness of the blade, a critical factor for swordsmanship.

If you're looking for budget options, suppliers like Kajiya Supplies offer more affordable steel varieties that still meet the standards required for crafting a durable blade. Although these options may have slight differences in quality compared to higher-priced alternatives, they can be suitable for beginners or those working within a limited budget. Remember, the quality of the steel directly impacts the blade's performance and longevity, so choose wisely based on your needs and priorities.

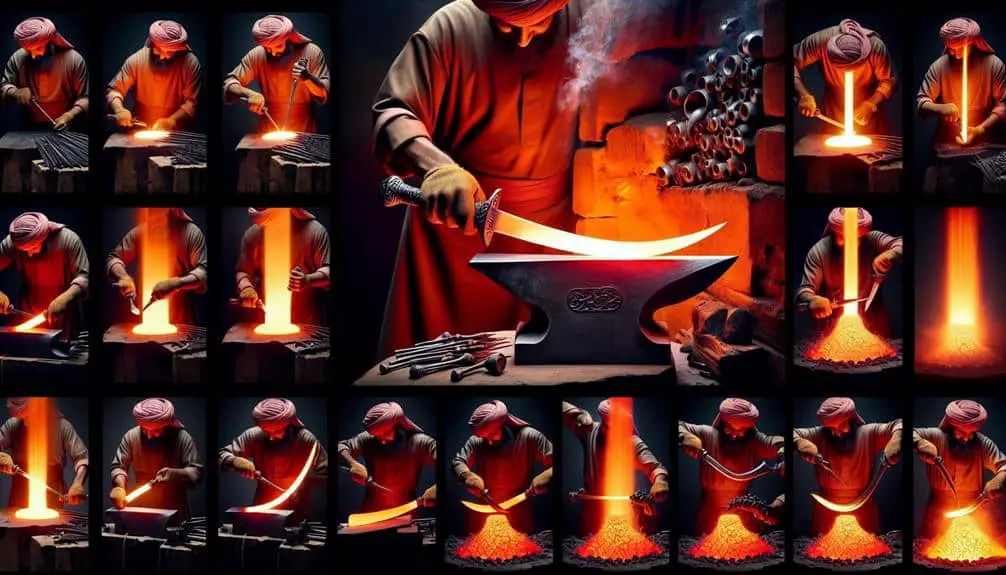

Forging the Blade With Ores

When crafting Nichirin Blades, incorporating high-quality ores is essential to ensure the blade's strength and sharpness. Ore selection plays a pivotal role in determining the quality of the final product. Different ores offer varying degrees of durability and sharpness, so choose wisely based on the desired characteristics of the blade.

Forging techniques are indispensable in working with the chosen ores. The process involves heating the ore to high temperatures and then shaping it through repeated hammering and folding. This method helps to align the ore's molecules, enhancing the blade's strength and sharpness.

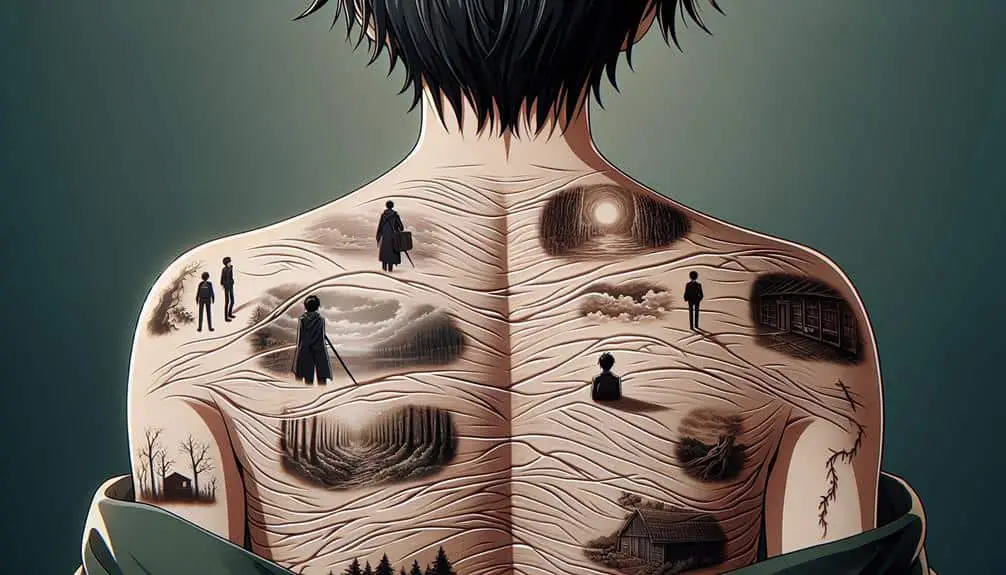

Color symbolism is also significant when crafting Nichirin Blades. The color of the blade represents the wielder's identity and abilities. Consider the symbolism behind each color carefully, as it adds depth to the blade's overall meaning.

Blade symbolism is another critical aspect to keep in mind during the forging process. The shape and design of the blade can convey specific messages, so pay attention to detail to create a blade that reflects the wielder's intentions and strengths.

Cooling and Shaping the Blade

Cooling and shaping the blade requires meticulous attention to detail and precision in order to achieve the desired form and properties. Once the blade has been forged and hammered into shape, it's important to cool it gradually to relieve any internal stresses formed during the intense heat of the forging process. This is typically done by placing the blade in a temperature-controlled oven and slowly decreasing the temperature over a period of hours.

After the cooling process, the blade is ready for shaping. The blade curvature, also known as the 'sori', is a critical aspect that impacts the sword's balance, strength, and cutting ability. Achieving the perfect sori involves careful heating and bending of the blade while monitoring the curvature closely. This step requires skill and experience to ensure the blade maintains its structural integrity.

Once the desired blade curvature is achieved, the sword undergoes the tempering process to enhance its hardness and durability. This involves heating the blade to a specific temperature and then rapidly cooling it to set the molecular structure. The careful control of temperature and timing during tempering is essential to produce a blade that's both strong and flexible, capable of withstanding rigorous use.

Adding the Colorful Finishing Touch

After meticulously shaping and tempering the blade, the next step involves infusing it with the vibrant and striking colors that will give it its unique and enchanting finishing touch. This stage is essential, as it not only enhances the aesthetic appeal but also imbues the blade with symbolic meanings through the colors chosen. To achieve a flawless finish, follow these steps:

- Creating Unique Designs: Before applying the colors, sketch out the design you wish to incorporate onto the blade. This design should reflect the essence of the wielder and the purpose of the blade.

- Selecting Colors: Each color holds a specific symbolism in the world of Nichirin blades. Choose colors that resonate with the blade's intended use and the traits of the wielder.

- Applying the Colors: Using specialized techniques, carefully apply the colors onto the blade, ensuring precision and consistency throughout the design.

- Final Touches: Once the colors are applied, inspect the blade for any imperfections and make necessary touch-ups to create a flawless and alluring finish that embodies the spirit of the wielder.

Testing the Blade for Power and Purity

To ensure the power and purity of the crafted Nichirin blade, rigorous testing procedures are meticulously conducted. Once the blade is forged and tempered, the next vital step involves evaluating its blade strength and spiritual energy.

The testing process begins by subjecting the blade to intense heat, simulating battle conditions to gauge its resilience and cutting ability. This test not only measures the physical strength of the blade but also its spiritual energy, which is essential for combating demons effectively.

After the initial heat test, the blade undergoes a series of precise strikes against various materials to determine its sharpness and durability. Each strike is carefully executed to gauge how well the blade maintains its edge and integrity under different pressures. The blade's ability to retain its sharpness and withstand these rigorous tests is a confirmation of its quality and purity.