When choosing between traditional and modern Nichirin blades, consider the evolution of blade designs. Traditional blades showcase intricate artistry and time-honored techniques. They excel in weight distribution and edge retention due to the craftsmanship in material selection and forging. Modern blades offer cutting-edge designs, superior sharpness, and durability. They utilize high-quality stainless steel and innovative alloys for optimized performance. The choice between the two depends on your preferences for craftsmanship and performance.

Key Points

- Consider traditional blades for historical authenticity and craftsmanship appreciation.

- Opt for modern blades for superior cutting performance and durability.

- Evaluate personal preferences based on cutting tasks and aesthetic preferences.

- Balance edge retention and sharpness needs when choosing between traditional and modern blades.

- Explore the blend of tradition and innovation to find the perfect Nichirin blade for your needs.

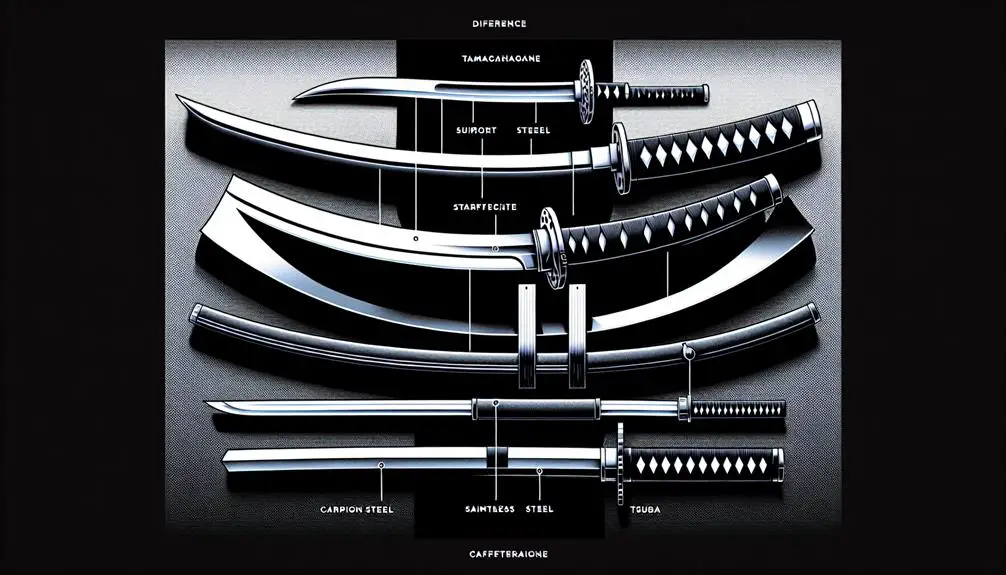

Evolution of Nichirin Blade Designs

Throughout history, Nichirin blade designs have undergone significant evolution, reflecting advancements in metallurgy and craftsmanship. The evolution of these blades is a proof of the innovative spirit of swordsmiths aiming to create the most effective weapons. Design innovation played an important role in shaping the form and function of Nichirin blades over the centuries.

One key aspect of the evolution of Nichirin blade designs was the refinement of blade shapes. From the early curved blades to the more standardized straight blades, each design iteration was a result of meticulous experimentation and feedback from experienced warriors. These changes in design not only impacted the aesthetics of the blades but also influenced their cutting capabilities and overall effectiveness in combat.

Additionally, the evolution of blade designs also saw improvements in the intricate details, such as the placement of the sword's guard and pommel. These design innovations weren't just decorative but served practical purposes, enhancing the balance and handling of the sword in the hands of its wielder. Understanding the evolution of Nichirin blade designs provides valuable insights into the craftsmanship and ingenuity of the swordsmiths who crafted these revered weapons.

Materials Used in Traditional Blades

In traditional Nichirin blades, a variety of materials, meticulously chosen for their properties, were utilized in the forging process to achieve the desired characteristics and performance. These traditional blades often incorporated tamahagane, a type of steel made from iron sand, known for its purity and ability to hold a sharp edge. The process of folding and hammering this steel created a blade with exceptional strength and flexibility, vital for withstanding intense combat. Additionally, the use of differential hardening techniques like clay tempering helped in creating a hard edge while maintaining a softer, more resilient spine.

Compared to modern blades, traditional Nichirin blades placed a strong emphasis on the craftsmanship involved in selecting and working with these materials. The combination of high-carbon steel for the cutting edge and low-carbon steel for the body resulted in a blade that offered a balance between sharpness and durability. Understanding the intricate interplay between these materials was essential for crafting a blade that could meet the demanding requirements of both combat and aesthetic beauty.

Advantages of Modern Nichirin Blades

Modern Nichirin blades have evolved greatly, incorporating cutting edge designs that optimize sharpness, durability, and overall cutting efficiency. These modern blades often utilize high-quality stainless steel or even innovative alloys, enhancing their strength and resilience. The manufacturing processes have also been refined, allowing for greater precision in blade shaping and edge retention.

One key advantage of modern Nichirin blades is their superior edge retention compared to traditional blades. The use of advanced materials and manufacturing techniques results in a blade that maintains its sharpness for a longer period, reducing the need for frequent sharpening. Additionally, modern Nichirin blades are often designed with specific cutting tasks in mind, leading to improved cutting performance and overall user experience.

Craftsmanship in Traditional Blade Making

Craftsmanship in traditional blade making showcases the intricate artistry and time-honored techniques passed down through generations, embodying a rich history of meticulous handcrafting. Artisan techniques are at the core of traditional blade making, involving a labor-intensive process that begins with selecting high-quality steel known for its durability and sharpness. The forging process is a critical stage where the master bladesmith meticulously heats, hammers, and folds the metal to create a strong and resilient blade with a distinct grain pattern. This process requires immense skill and precision to guarantee the blade's integrity and cutting ability.

The traditional blade making process also involves the careful shaping and grinding of the blade to achieve the desired shape and edge sharpness. The bladesmith's expertise is evident in every step, from the initial forging to the final polishing, where the blade's beauty and functionality are perfected. Each traditional blade is a proof to the dedication and mastery of the craftspeople who continue to preserve these ancient techniques and create blades of exceptional quality and craftsmanship.

Performance Comparison: Traditional Vs Modern

When comparing the performance of traditional and modern blades, one must consider their respective strengths and weaknesses in practical applications. Traditional Nichirin blades, crafted with centuries-old techniques, often excel in weight distribution and edge retention. The careful forging methods employed by skilled artisans result in a blade that feels balanced in your hand, aiding in precise cuts. Additionally, the high carbon content in traditional blades enhances their edge retention, allowing for prolonged use before requiring sharpening.

On the other hand, modern Nichirin blades are known for their exceptional cutting power and blade flexibility. The advanced metallurgy techniques utilized in modern blade manufacturing produce edges that exhibit superior sharpness, making them ideal for intricate cuts. Furthermore, the flexibility of modern blades enables them to absorb and disperse impact energy efficiently, reducing the risk of breakage during heavy use or sudden movements.